Table of Contents

Related Blogs

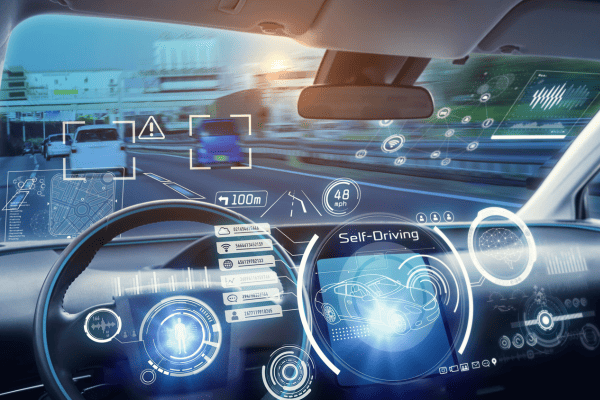

The automotive industry is a tech industry. If you don’t believe me, look no further than Tesla, who will sell you a $50k supercomputer that comes packaged with a car. At the highest level, software powers everything from engine performance and safety to entertainment and navigation. In-car software and applications provide real-time diagnostic data and seamlessly integrate (the driver hopes) with smartphones and other devices.

Over-the-air software updates that keep cars up to date with the latest applications and performance enhancements are also becoming more common. We have seen this technique employed by VinFast, a Vietnamese EV manufacturer who, when faced with public backlash over the performance and capabilities of their vehicles, promised to make changes in future software updates.

The Industry Changes with the Technology

There are two main factors at play when discussing software testing for the automotive industry:

- With tens of millions of lines of code per average in each car, Original Equipment Manufacturers (OEMs) must write, integrate, test, and deploy code quickly and efficiently. They use advanced techniques to accelerate the process (more on that in a bit).

- Simultaneously, the software in development has evolved from assisting with engine and infotainment functionality to driver assistance systems and autonomous driving, which increases testing complexity.

At the same time, developer sprints are shortening, and the demand for flawlessly functioning applications pressures OEMs to push their new features closer to the start of production. Developers and testers need shorter feedback loops (enabled by continuous testing) to update code continuously.

These Changes Come in Some Familiar Ways

Like many other industries in the 2020s, the automotive industry embraces Agile development, which opens the door for accelerating other processes, like DevOps delivery focusing on continuous testing.

This shift towards iterative development, where teams continuously write, integrate, and test their code, suits OEMs well. APIs integrate applications and functionality in a continuous integration/continuous delivery (CICD) environment, which allows developer teams the ability to update code throughout the life of a vehicle, taking the most successful code and reusing it elsewhere to minimize errors and reduce costs.

Bracing for Impact

Thanks to increased digital transformation across industries, cars are evolving into interconnected machines reliant on software systems to operate to their full potential.

The first use case that comes to mind is engines and drivetrains. Engine Control Units (ECUs) help optimize performance and fuel efficiency. These ECUs use algorithms to manage fuel injection, ignition timing, and other parameters, resulting in better fuel economy and reduced emissions. In some high-end supercars, these parameters are customizable, giving drivers a unique driving experience tailored to their preferences.

There is more beyond performance. In a world obsessed with safety, the automotive industry is rolling out software as part of its main innovations. Advanced driver-assistance systems (ADAS), such as lane-keeping assistance, adaptive cruise control, and automatic emergency braking, rely heavily on software algorithms. With capabilities that can apply brakes or turn in case of an impact, this software is helping reduce accidents and save lives.

The use case that is most relevant to our discussion is the seamless connectivity offered by infotainment systems. These systems provide many features, from smartphone integrations to navigation, voice recognition, and many other in-car apps. Tesla’s infotainment system even has a whoopie cushion option to help make driving more convenient and, dare I say, fun. This increase in complexity is what necessitates the need for automated continuous testing to ensure reliability.

The Challenges of Developing and Testing Automotive Software

As we dig into the challenges, we need to separate the lists because there are two layers to this. There are challenges in testing automotive software overall and in testing infotainment systems. Let’s take a closer look at both.

Automating continuous testing in the industry at large presents the following challenges:

- Safety-Critical Systems: Ensuring that advanced driver assistance systems (ADAS) function flawlessly is essential. The main challenge is creating automated tests that can rigorously simulate real-world scenarios to test these capabilities.

- Complex Integrations: These systems are all interconnected, starting with those ADAS systems and continuing through engine control and infotainment. The challenge here is in the complexity of these systems and the ability to maintain compatibility across vehicle models.

- Compliance: As a highly regulated industry, testing efforts must align with current regulations to ensure and demonstrate compliance.

- Data Volume and Analysis: We all know the vast amount of data generated by continuous testing processes. Now add to that the complexity of automotive systems, and you will get an idea of how important and hard it is to analyze the data to identify issues and make improvements.

- Legacy Systems: Older cars still use legacy software and hardware systems. However, these systems must still be supported and maintained as the rest of the product line shifts to newer systems and testing processes to ensure compatibility.

Let’s drill down further into the nature of infotainment and unpack some of the challenges of testing those systems:

- User-Centric Testing: Automated tests must emulate real user interactions as infotainment systems serve the end-user. Testing needs to focus on UX usability and UI design.

- Integrations: These systems integrate with other vehicle systems like safety and navigation. Testing must ensure these integrations are seamless and do not compromise vehicle performance.

- Multimodal Interfaces: With support for voice commands, touchscreens, physical buttons, and gestures, each interface must be tested to ensure consistent behavior across the board.

- Content and Connectivity: Infotainment systems use different content sources like streaming services, smartphone connectivity, and over-the-air updates. Testing must account for all those content formats, network conditions, and compatibility.

- Performance and Resource Usage: These systems must run efficiently so as not to impact overall vehicle performance. Performance testing needs to analyze CPU and memory consumption to ensure system responsiveness.

AI and ML are Becoming Part of the Assembly Line

When we talk about automated testing in the automotive industry, which is constantly looking forward to the most innovative developments, we need to outline how to employ AI and ML to test these systems.

- AI-powered Test Creation: Using AI algorithms like natural language processing software, requirements can be analyzed to generate test cases. It reduces the time and effort needed to create tests manually.

- Intelligent Analytics: Automated testing generates a lot of data using Machine Learning to analyze test results and identify defect patterns, which will help testers prioritize and focus on critical issues.

- Predictive Intelligence: Using ML models to train on historical data helps identify patterns correlating with software defects. The models can then use that training to predict the likelihood of defects in new code, proactively eliminating issues before they become a problem.

- Self-Healing: Broken test cases can be healed automatically during test executions, helping to reduce the burden of test maintenance. It ensures test suites will continue running as the software grows and evolves.

AI and ML are helping revolutionize automated testing for car manufacturers by automating repetitive, time-consuming tasks. AI and ML help improve the reliability, effectiveness, and efficiency of the testing process. The result is higher quality software delivered at scale and quickly.

Some big manufacturers are already employing these techniques:

- Tesla uses AI to analyze fleet data and identify potential defects. This data is used to improve in-car software.

- GM uses machine learning for predictive intelligence to address defects in new code. They use that data to prioritize testing efforts.

- Ford generates test cases for their infotainment system using AI. It helps them reduce the time and effort needed to create test cases manually.

The automotive industry is becoming increasingly reliant on software, so continuous testing is emerging to address quality and reliability issues. It is not without challenges, as ADAS systems, interconnected components, and data analysis require a strong testing process.

AI and ML techniques continue to emerge and revolutionize automated continuous testing by automating repetitive tasks and improving the effectiveness of tests, which helps with defect prediction and identification.

Embracing automated continuous testing and leveraging AI and ML will help automotive manufacturers deliver high-quality, reliable software to their cars quickly and reliably. It will ensure that the future of the automotive industry is innovative, safe, and interconnected.

Revolutionize your automotive software testing with Digital.ai’s Continuous Testing solutions – where innovation meets reliability in the fast lane!

Are you ready to scale your enterprise?

Explore

What's New In The World of Digital.ai

Guide: Mobile Automation with Appium in JavaScript

Learn to automate mobile apps with Appium and JavaScript. Our guide includes setup, test writing, and advanced features to streamline your testing process.

Digital.ai Testing Now Supports iOS 26 Beta

Digital.ai Testing now supports iOS 26 (Beta). Discover the new features and see how it works with a demo below.

Beyond Automation: How AI is Transforming Enterprise Software Delivery

Discover how AI in software delivery is revolutionizing enterprise software by automating tasks, enhancing UX, and transforming the SDLC.